Carbon Neutral QPRESS® Technology Successfully Commissioned for Cameron Bay STP

August 15, 2023

TasWater’s Cameron Bay STP was recently upgraded to allow the Sludge Dewatering Facility to meet new performance requirements, reduce maintenance and increase reliability.

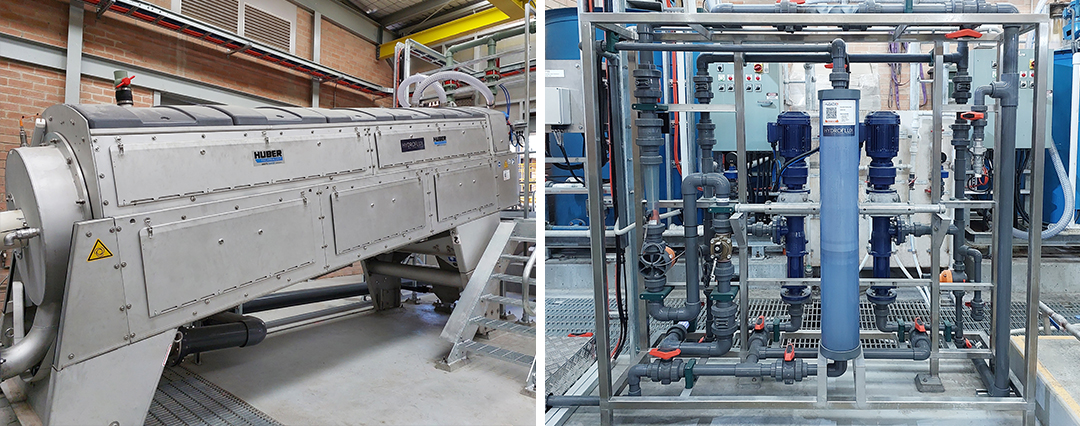

The existing sludge dewatering facility consisted of a maintenance intensive belt filter press that consumed high amounts of washwater and produced low sludge volume reductions. Hydroflux were contracted to supply and commission a new HUBER Rotary Screw Press to dewater the anaerobic digested sludge.

Sustainability Highlights

- QPRESS® is Climate Active Certified as Carbon Neutral, a first for the Australian Water Sector

- Hydroflux, as an organization is Climate Active Certified as Carbon Neutral

- Low energy low speed technology (90% less as compared to high speed technologies)

Project Highlights

- Dewatering of anaerobically digested sludge

- Performance guarantees met

- One of several QPRESS® installations for TasWater

Technology Highlights

- Low speed screw press, less than 1rpm internal speed, low maintenance requirements

- Triple staged internal wedgewire basket provides high performance and durability

- Patented internal wiper allows effective basket clearing and is extremely durable

- All stainless steel construction for internals, lids and main case

- Low washwater consumption (less than 1000 L/h)

QPRESS® is a sludge dewatering technology that is used in municipal and industrial wastewater treatment plants. It provides a high level of sludge volume reduction that minimizes offsite disposal costs and being low speed, the technology is far less maintenance intensive as compared to high speed technologies.

CLICK HERE to learn more about QPRESS® or call Hydroflux on 1300 417 697.

Up Next

Brewing Beyond ABV: A Solution to an Increasing Demand

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement