Brewing Beyond ABV: A Solution to an Increasing Demand

August 17, 2023

The beverage industry faces a significant challenge when it comes to reducing the alcohol content in beverages. With the increasing demand for low-alcohol or alcohol-free alternatives, brewers are seeking ways to cater to consumer preferences without compromising on taste, aroma, or foam stability. Traditional methods of alcohol reduction, such as distillation, often fail to preserve the distinct taste profiles of alcoholic beverages, leading to a loss of essential flavour and aroma compounds. Moreover, these conventional techniques demand high energy inputs, resulting in elevated production costs and a substantial environmental impact.

Solution: NX Filtration’s Nanofiltration Technology Revolutionises Dealcoholisation

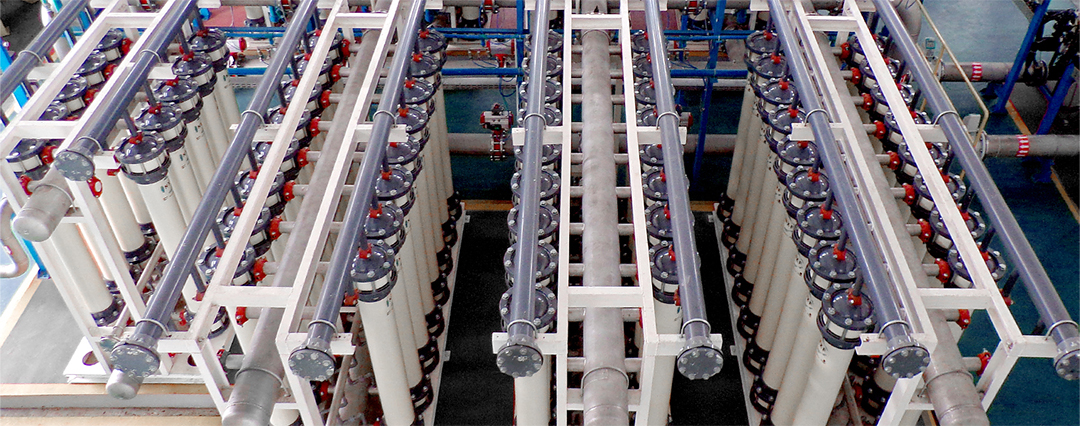

NX Filtration offers a groundbreaking solution to the alcohol reduction challenge through its innovative nanofiltration technology. By leveraging nanofiltration membranes, NX Filtration provides a gentle and precise process for reducing alcohol content in beverages while preserving their unique taste profiles. The nanofiltration process excels at retaining complex and delicate components like flavour, aroma, and colour, making it an ideal choice for maintaining the essence of alcoholic beverages.

Unlike traditional spiral wound nanofiltration membranes, NX hollow fibre membranes perform extremely well when treating all types of beverages, including brews which retain a high content of solids. The hollow fibre membranes do not foul and can be easily cleaned with automated washing and sanitising systems.

Key Benefits of NX Filtration’s Nanofiltration Process:

Preservation of Distinct Taste Profiles: The nanofiltration process selectively removes ethanol without compromising the sensory experience, ensuring that low-alcohol or alcohol-free versions of beverages closely resemble the characteristics of the original ones.

Energy Efficiency and Cost Reduction: Unlike traditional distillation techniques, NX Filtration’s nanofiltration operates efficiently under mild process conditions, such as low temperatures and pressures. This energy-efficient approach significantly reduces production costs and minimizes the environmental footprint.

The Process Behind NX Filtration’s Dealcoholisation:

NX Filtration’s hollow fibre nanofiltration membranes play a crucial role in the dealcoholisation process. These membranes allow small molecules, like water and ethanol, to pass through while effectively retaining and preserving complex components like flavour and aroma. The batch process involves concentrating the beverage to 40% of its initial volume, followed by replenishment with deaerated water to restore the original volume. The nanofiltration process selectively removes ethanol during this step, leaving behind a low-alcohol or alcohol-free beverage with its authentic characteristics intact.

Partnership with Hydroflux: Expanding the Reach of Dealcoholisation

To further enhance its dealcoholisation capabilities and strengthen its presence in the market, NX Filtration has partnered with Hydroflux, a prominent player in the beverage industry. This collaboration aims to leverage Hydroflux’s expertise to refine and expand the application of NX Filtration’s nanofiltration technology. The ultimate goal is to provide breweries of all sizes with a practical and scalable solution for meeting the increasing consumer demand for alcohol-low and alcohol-free beverages.

With NX Filtration’s nanofiltration technology and the strategic partnership with Hydroflux, the beverage industry can now embrace a sustainable and consumer-focused approach to dealcoholisation. This solution not only addresses the demand for low-alcohol alternatives but also sets a precedent for energy-efficient and environmentally friendly practices within the sector.

About the Hydroflux Group

The Hydroflux Group aims to deliver the highest level of engineering and scientific know-how to the emerging issues of sustainability, climate adaptation and environmental protection with a specific focus on water and wastewater.

As part of its vision and mission, Hydroflux has always taken its climate responsibility seriously. In 2022, Hydroflux became Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for its organisation and products. It knows that partnering with customers and clients is the most significant impact it can have in its journey.

The Group employs over 100 staff and operates throughout Australia, New Zealand and the Pacific Islands, with office locations in Sydney, Melbourne, Brisbane, Perth, Auckland, Suva and Portsmouth.

Up Next

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement