An Example of Delivering Increased Screening Capacity at STP Inlet Works

January 21, 2025

Increasing screening hydraulics through an inlet works can be challenging. Consideration of water levels, headloss, weir levels, freeboard and failure conditions need to be addressed.

Recently Hydroflux provided a high surface area HUBER RakeMax® HF Screen to boost inlet works capacity for one of Sydney Water’s Water Recycling Plants. After considering the items above and working with the head contractor in terms of hydraulics, the new screen was able to pass 35% more capacity than the previous step type screen installation with increased screenings capture.

Project Highlights

- Increased screenings capture through the existing inlet works

- Increased hydraulic capacity by 35%

- Retrofit within an operating treatment plant, with minimal channel modifications

- Review of channel hydraulic profile, freeboards and water levels

Technology Highlights

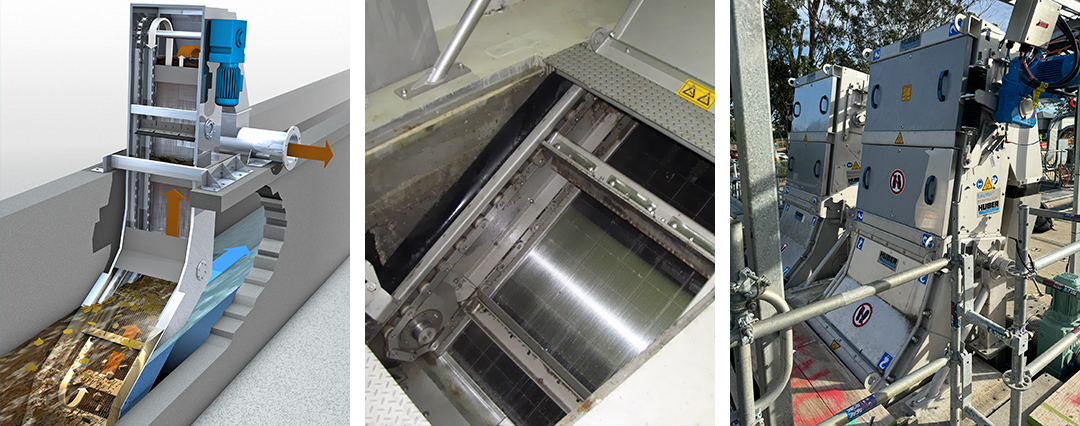

- RakeMax® HF was selected – due its low angle screen, higher capacity was achieved

- Unique multi rake 4mm wedgewire configuration increases screenings capture – the 3mm version is UK WIR certified for 75% capture

- Flow testing onsite confirmed headloss values and capacity

- All stainless steel fabrication

RakeMax® HF is a multi-rake bar screen with a low angle submerged screen area that allows high contact area that increases capacity. For this project the screening medium was 4mm wedgewire. A special two staged multi rake cleaning system removes screenings from the wedgewire panels and carries the debris to the machine’s discharge point.

The screen is available in widths from 500 to 2500mm and at 12 different discharge heights to suit any channel geometry. Capacities range from 50 through to 3000 L/s.

To learn more please contact our team on 09 352 2052 or visit www.hydrofluxepco.nz.

About the Hydroflux Group

The Hydroflux Group aims to deliver the highest level of engineering and scientific know-how to the emerging issues of sustainability, climate adaptation and environmental protection with a specific focus on water and wastewater.

As part of its vision and mission, Hydroflux has always taken its climate responsibility seriously. In 2022, Hydroflux became Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for its organisation and products. It knows that partnering with customers and clients is the most significant impact it can have in its journey. The Group employs over 100 staff and operates throughout Australia, New Zealand and the Pacific Islands, with office locations in Sydney, Melbourne, Brisbane, Perth, Auckland, Suva and Portsmouth.

Up Next

Managing Grease Trap Waste and Tanker Receival Facilities

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement